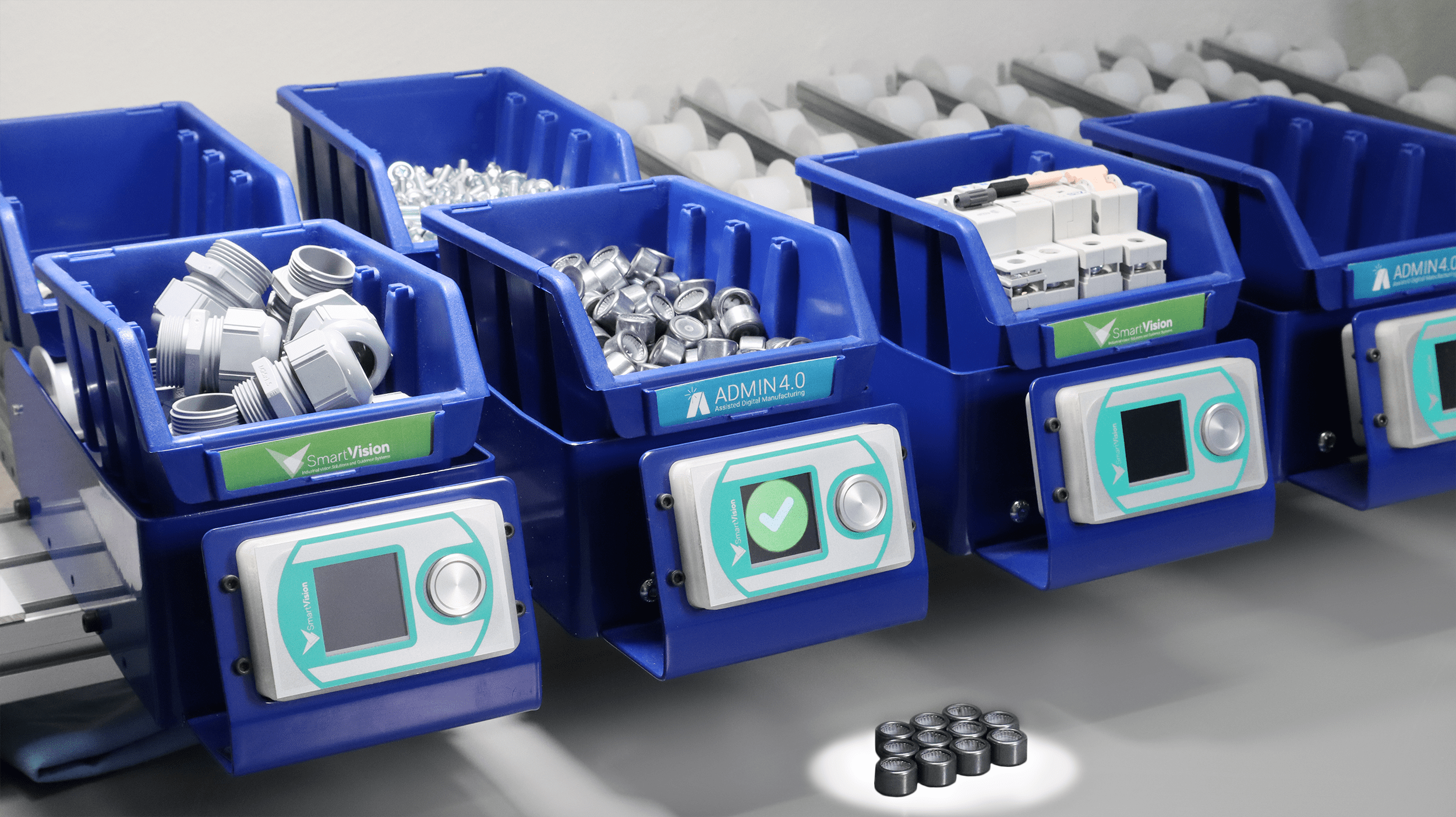

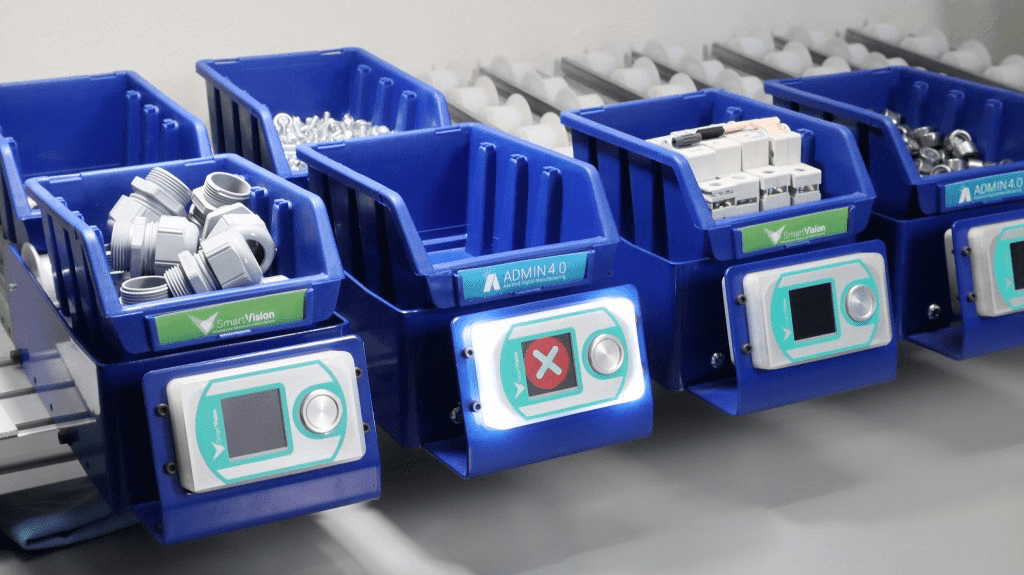

Experience the future of cutting tool production with ADMIN4.0

In 2020, we commenced a significant partnership with Karel Kaňák s.r.o., a Czech company. This collaboration not only provided us with valuable practical insights into deploying our ADMIN4.0 assisted production system but also led to the development of a product that was previously scarce in the market. The “Kaňáci” demonstrated a clear understanding of their…