Projection of signs, images or CAD drawings into the operator’s workspace to guide and signal actions. By using video or laser projector technology with variable projection range and also by combining multiple projection devices into a single image, any space can be covered and a precise and high contrast projection can be set up for any material.

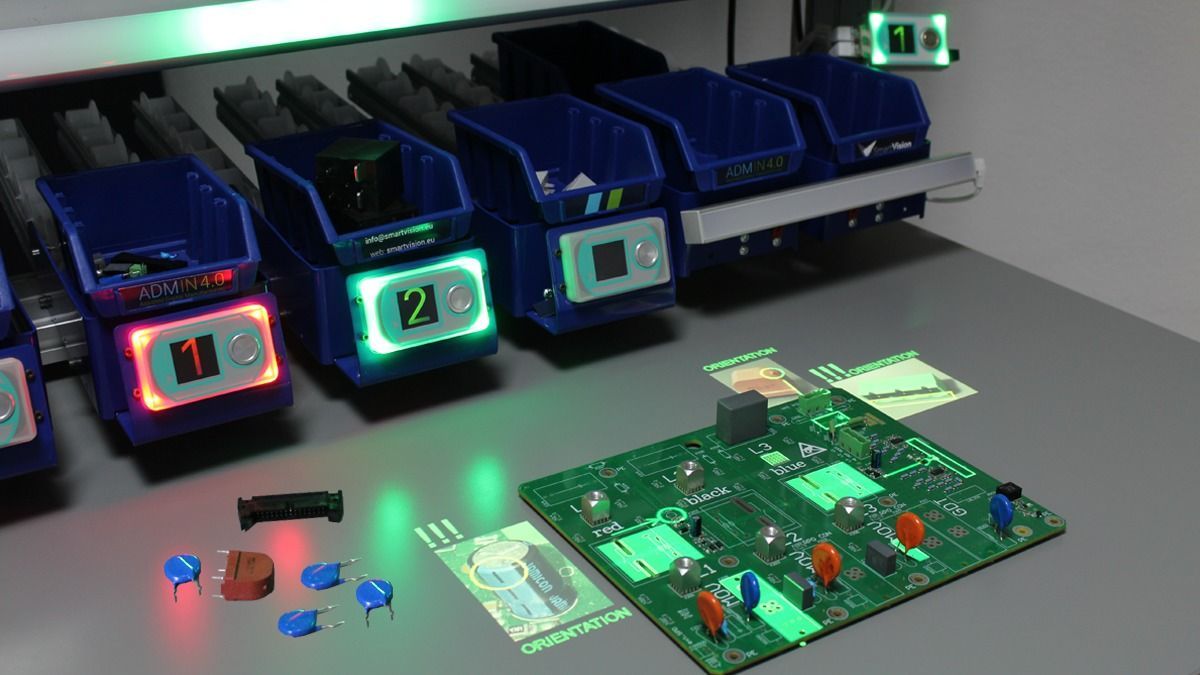

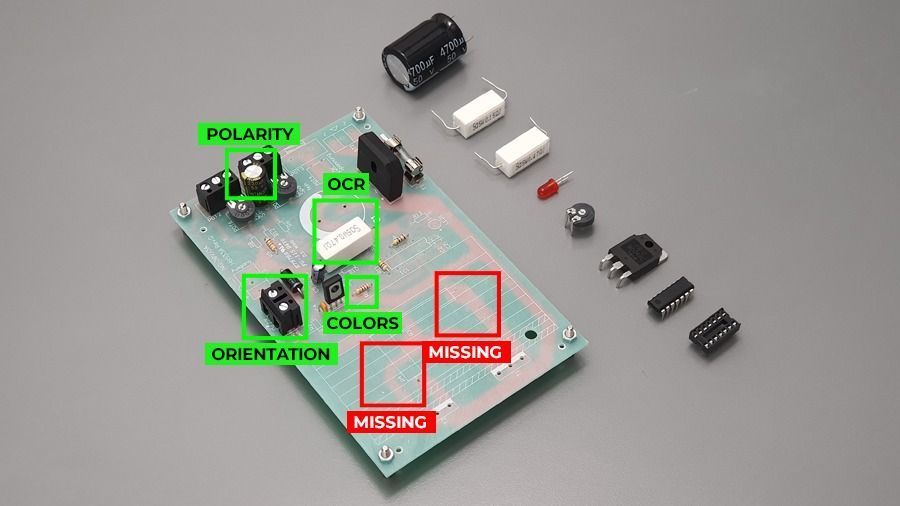

The ADMIN4.0 system combines visual guidance with a camera system to not only provide visual guidance, but also to check the correct positioning and orientation of parts. With the learning system, computer vision becomes routine and does not require specialist knowledge.

The system uses the camera to detect the position of objects in the workspace and adjusts the position of both the visual guidance and quality inspection to match their exact location. Handling thus becomes flexible without the need to fix the products in a precise position.

Long-term data storage and analysis helps to detect bottlenecks in the process, predict production, pace and trace back defective operations in case of a complaint. The database can be accessed locally at the station or from a remote computer on the network.

The Pick to Light system for light guidance to the correct material when mounting the board is an essential control for component inspection. The system displays the number of components to be picked up for the assembly operation and also checks the quantity picked up using a weight counter. It displays images using an OLED display and can be expanded with additional peripherals.

A procedure is a set of functional steps that represent a production process. They can be easily and interactively defined and the operator perceives on the monitor all available information such as the description of the action and its display, the time it takes to perform it and other optional information.

The monitoring of the operator’s hand position and handling within the workplace is one of the preventive functions of ADMIN4.0, which gives an early warning of incorrect actions. Hand position recognition also enables fast material removal from the “FastPick” boxes, where the system anticipates the next material position for assembly and the system signals it before the operator completes the assembly operation.