30 years of history of the AMPER exhibition offered us a challenge in the form of our historical first participation in this exhibition, which we did not refuse and participated as exhibitors. We focused on electrical industry applications and the interest came from the crowd. We offered visitors a cocktail of our proven classics in the form of visual guidance and control during the installation of THT components and a detailed inspection of the correct installation, as well as a look into the future and at the same time the presence of digitization of processes using AR devices.

At the exhibition, we presented our 4 main exhibits – the most complex is certainly our visual guidance and control workplace ADMIN4.0 and also the Bridge module for a simple All-in-one installation, which contains all elements of digitization such as the aforementioned visual guidance and instructions, camera control, tracking hands and materials or checking packaging. Robotic collaboration, processing of production data, digitization of processes and tools, as well as material flow and management are certainly advantages. It ensures a very efficient process from order to deployment. The entire system is created in such a way that self-installation with support for remote start-up will speed up the placement and thereby simplify handling for the customer as much as possible. The ADMIN4.0 software, a zero-code platform for simple configuration of a Smart factory using AI, AR and robotics, is the main part of this workplace and at the same time a powerful tool for a really wide range of industries.

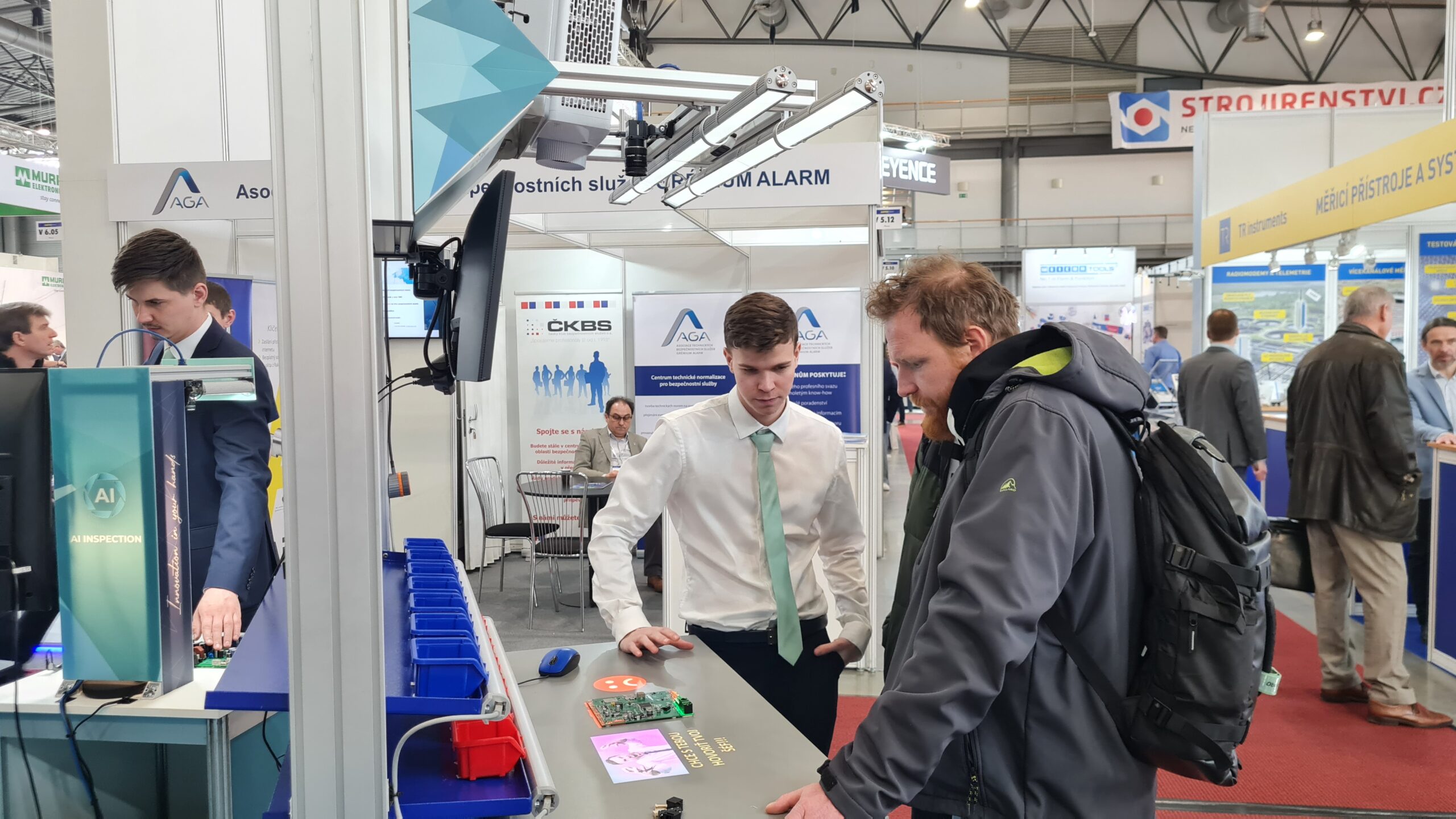

Visual guidance and control workstation for THT

The assembly workplace of THT components represents visual guidance using a video projector, camera and inspection system, and pick-to-light material management, which is crucial in controlling and managing the flow of material from the warehouse to the workplace and the assembly itself. It makes it possible to increase the operator’s efficiency, eliminate the error rate, and minimize the training time of a new worker.

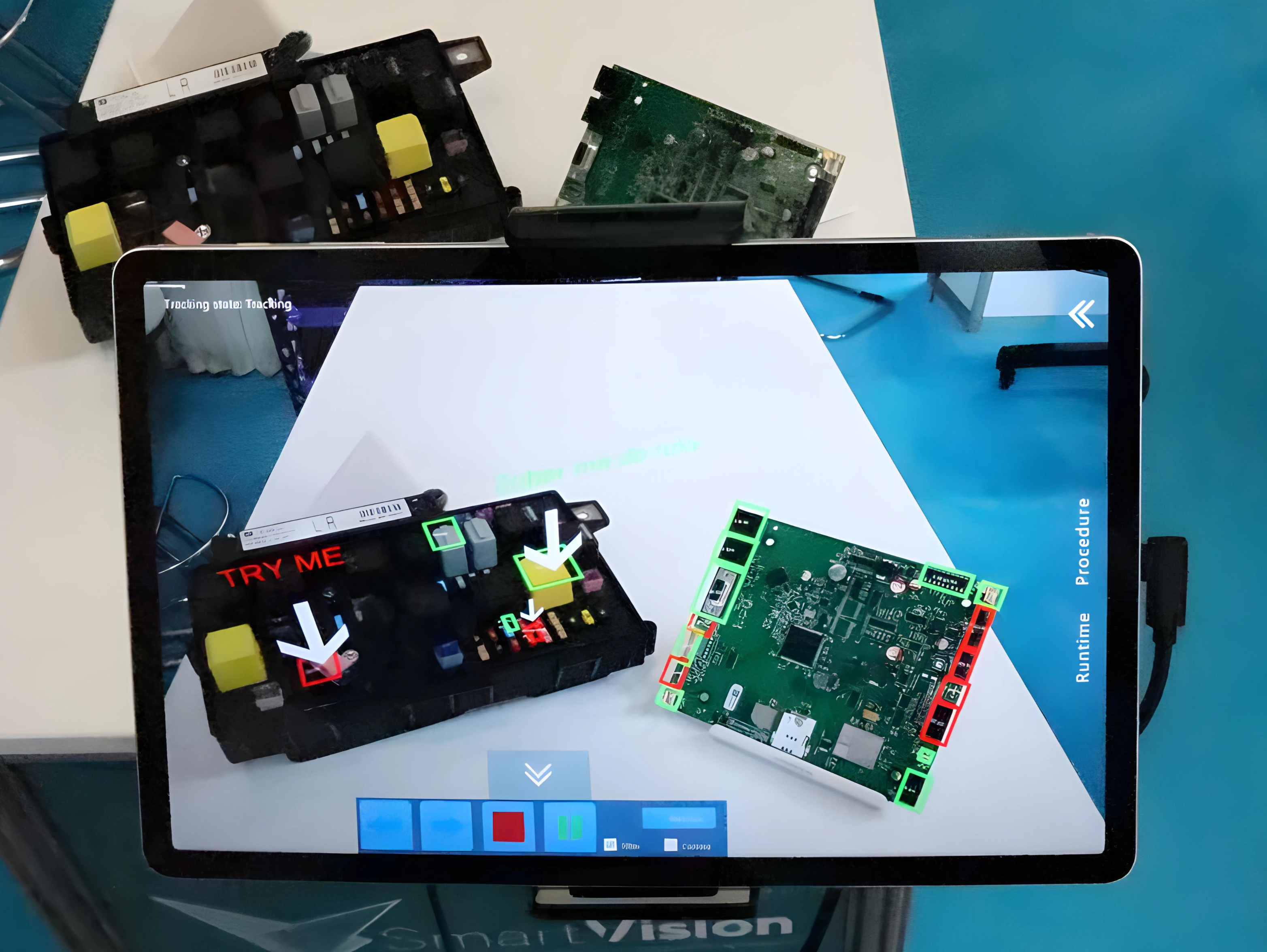

AR mobile quality control

Another product was Admineo – augmented reality, which with the help of AI enables comprehensive quality inspection, assembly assistance, machine and equipment operator instruction as well as accurate placement of THT components, detailed control of the presence of components, their correct storage, and polarity. A big advantage is the very fact that it is a mobile work tool in the hand, which offers a view from several angles and sides and is portable between stations.

Inspection station using artificial intelligence

The smart glasses in connection with the AI inspection station caught visitors’ attention. They provided visitors with augmented reality thanks to the connection with the quality control system.

All of the presented systems and products can be used in various manufacturing processes, such as quality inspections, quality control, anomaly and defect detection, packaging control, pallet completeness control, detection of the position of objects and their counting, shape analysis, and workplace monitoring.

AR mobile quality control