In 2020, we commenced a significant partnership with Karel Kaňák s.r.o., a Czech company. This collaboration not only provided us with valuable practical insights into deploying our ADMIN4.0 assisted production system but also led to the development of a product that was previously scarce in the market. The “Kaňáci” demonstrated a clear understanding of their requirements, and through the capabilities of our software, we were able to surpass their expectations.

The company Karel Kaňák s.r.o. specializes in manufacturing cutting tools for a diverse global client base. The intricacies of cutting tool production and its operational mechanisms revealed a transformative process that has propelled the company to global success. We had the privilege of enhancing operational efficiency and integrating it with a digital visual guidance environment.

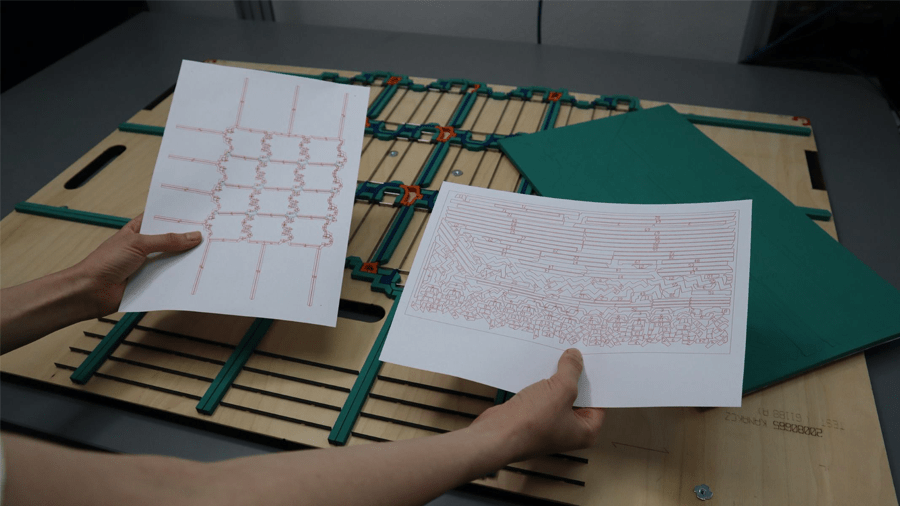

Our task was to revolutionize the gluing process of the die-cutting tool with rubber parts, eliciting immediate admiration from the operators. The process involved meticulously affixing hundreds of pre-cut rubber parts onto the die-cutting plate, all according to the pattern on the tablet.

Imagine a complex yet captivating puzzle, where the cameraman is at the helm all day with only a few actors. This scenario would be the norm if time didn’t play a role in pushing everyone forward.

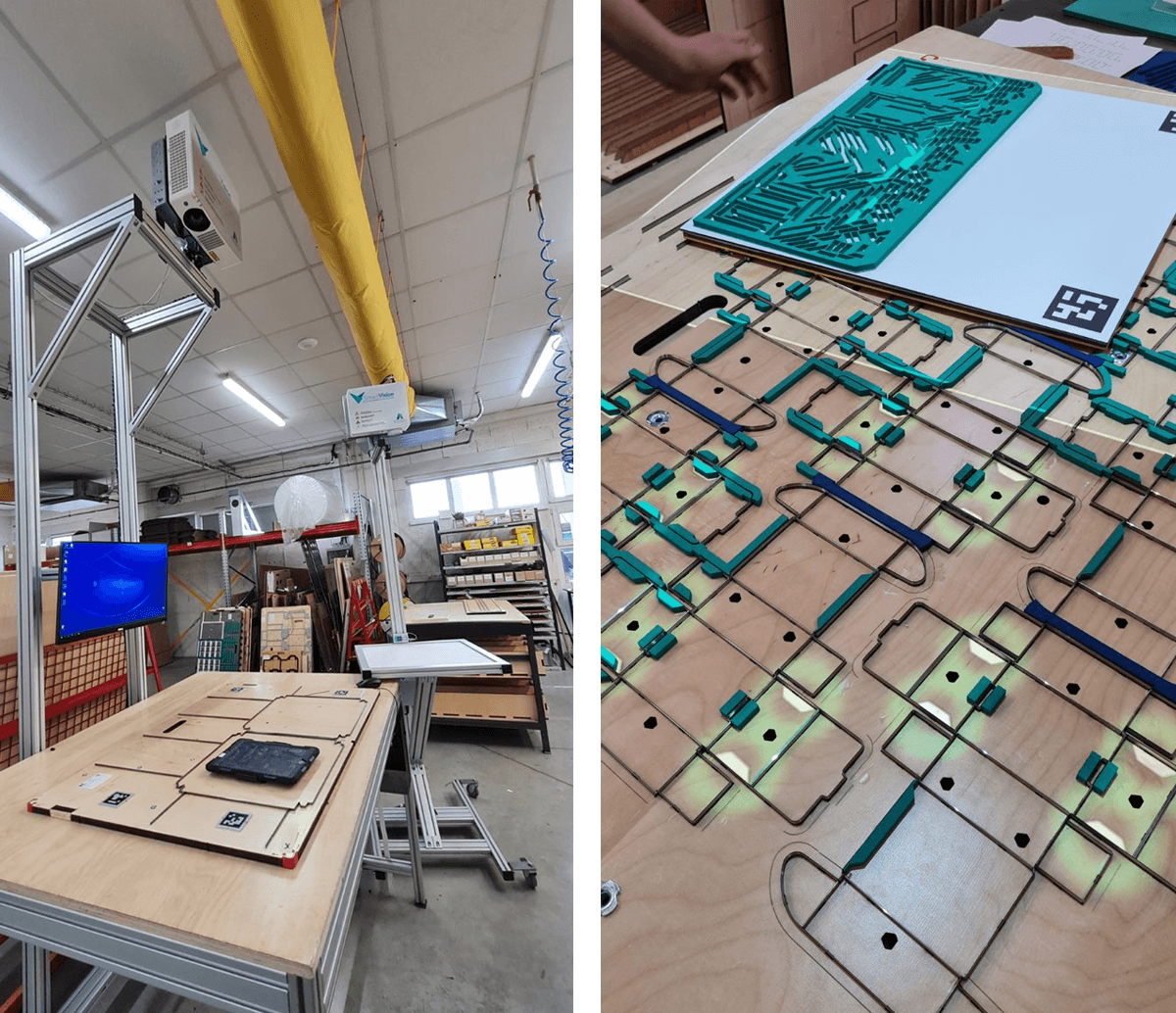

It was here that the space for our visual projection system was created. With precise guidance, we mark the places on the rubber plate from which the operator should take the rubber part, as well as the places on the cutting plate where to stick it. The camera provides the operator with freedom due to detecting the position of the rubber plate and the cutting tool, while also checking the correct positions of each part on the plate and the board. The gluing process has become fun, as the operator is no longer under time stress. It is also an ideal process for the ADMIN4.0 system, which guides, checks, and relieves the operator of time pressure.

The system’s development continued, and the configuration of the workplace and its ergonomics changed over time. The initial project had two workstations, each equipped with a video projector for visual guidance, a camera system for position detection and parts inspection. One workstation was designated for the die-cutting tool, and the other for the rubber plateau. This workstation, also known as the “satellite,” was mobile and could move along the main table by the operator.

The workplace concept, despite its successful operation, required a change in terms of ergonomics. It was necessary to combine two workstations into one table so that the operator did not have to constantly turn around to access the “satellite” equipment.

However, implementing this functionality required extensive development. It enables independent operation with a cutting tool and an alignment plate in the same workspace. Additionally, it can be customized to any size by connecting the projectors and cameras into a single unit.

The system development for your operation has been successfully completed and implemented by Austrian customers in Vienna and Salzburg, thanks to the innovative enthusiasm of Vladislav Polášek, the director of Karel Kaňák, s.r.o.

What were the results? Well, we were able to increase the gluing process speed by 20% for experienced operators, and for inexperienced operators, it was up to 5 times faster than what was measured by the Austrian manufacturer B&P Stanzformen. These impressive numbers clearly support the use of visual guidance and emphasize its importance for training new employees.

The excellent cooperation with the Kaňák firm was the driving force behind this project. Join our innovation revolution and let’s create a solution according to your ideas together.

Thank you.