It was with great pleasure that we welcomed visitors to the DIGITAL FACTORY Pavilion at the Brno Exhibition Center to showcase SmartVision’s vision of modern industry. Our exhibition encompassed demonstrations of assisted production, quality inspection at the workplace, as well as the integration of the quality system into the working environment.

The exhibition elicited varied responses from visitors, with children taking particular delight in the assembly workplace due to its light interaction and engaging work format. For some, the visual guidance alone provided a sense of complete control over the machinery. However, our fundamental objective remains centered on quality and efficiency, emphasizing the efficacy of human-machine collaboration in delivering innovation.

We also provided a video preview of our display, and we welcome any interest in arranging a presentation in either Bratislava or Brno.

Assembly Workplace with ADMIN4.0 visual assistance

This section showcased the use of the ADMIN4.0 system for procedural control of assembly through visual guidance

The workspace is under surveillance by a camera system capable of recognizing the position of the parts and subsequently adapting the visual guidance to deliver a meticulously calibrated laser beam. Moreover, the camera assesses the quality and accuracy of the assembly operations, verifies proper hand positioning, and facilitates control-free system operation. Notably, the precise “Pick-to-Light” guide encompasses color signaling, a counter, and component weighing, thus presenting an exclusive inspection solution.

Through extensive interactions, the ADMIN4.0 system stands as a flawless visual interface bridging the gap between humans and machines.

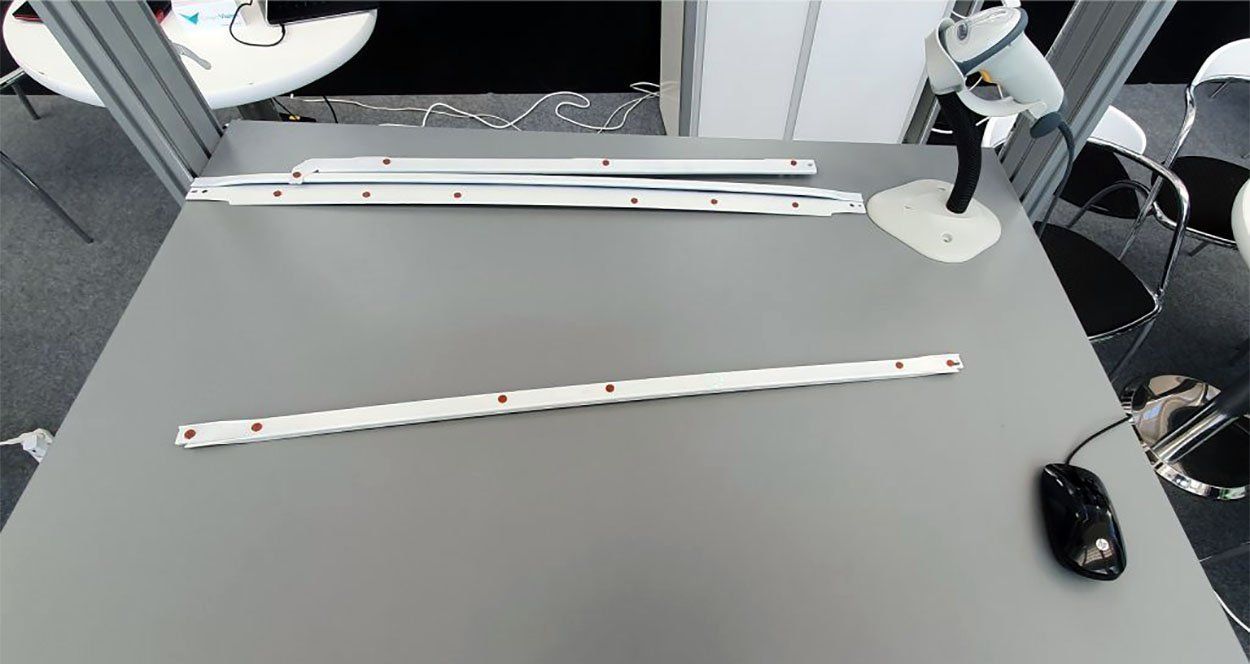

Inspection Workplace for Checking the Correctness of the Execution of ADMIN4.0

This exhibit highlighted the ADMIN4.0 system’s role in verifying the precise placement of small rubber seals on products

Each product was differentiated by barcodes for easy identification, and the required inspection program could be set using a barcode reader. The camera identified the product’s position on the table, checked it using defined references, and pinpointed assembly errors with laser visualization, showcasing the flexible utilization of the ADMIN4.0 system.

Implementation of the ADMIN4.0 System in the Assembly Workplace

It is sufficient to position the camera above the workstation, implement a control program, and enable the system to operate in support of the worker. Throughout the process, the product is consistently monitored, allowing the system to determine its accuracy before the worker completes the assembly.

ADMIN4.0 serves as a quality control system and is demonstrated through its seamless integration into the assembly workplace.

We extend our sincere thanks to all visitors for their keen interest and for contributing to the fantastic ambience at the fairgrounds.

SmartVision team.