The idea of modernization of the manufactory is clear – machines, automation, and robotization. More robotic hands and fewer problems, but what if human hands are irreplaceable in your production? Is it a dead end or just an opportunity to think differently?

Smart Vision, a company from Slovakia, has taken a different path and developed a system for cooperative operator guidance and quality control, which uniquely supports manufactory production instead of automation by machines. Increasing efficiency and reducing work errors means directly linking the worker to the computer so that the system not only guides but also controls the work performed. At the same time, it makes sure that it does not restrict the worker, thus naturally creating man-machine cooperation.

“Reduction of error rate to zero, doubling of the rate and tripling the speed of new employee onboarding sounds like a cliché, but the right digitalisation tools will actually make it possible.”

Visual guidance and projection

Visual operator guidance is the creation of a virtual space using projection equipment directly at the workplace. It enables the operator to visually mark the actions required to correctly make the product and inform him or her about the correctness of the work performed. Don’t imagine a pair of virtual goggles that you couldn’t stand to have on your head for more than half an hour. The projection visualizes directly on the surface of the component the operator is working with. The worker is thus shown information directly at the point of fabrication.

In this way, the system eliminates the operator’s head from the production process and takes control of the production rate. It is the precise visualization of the tasks with light that relieves the operator’s head, thus eliminating errors caused by inattention and lack of concentration. Covering the area from the workbench to the assembly hall allows for innovation in unlimited possibilities.

Pick to Light

The visual guidance system can be called the head and hands of the operator, but the essential job is not only to execute it correctly but also to take care of the correct material used for assembly or completion.

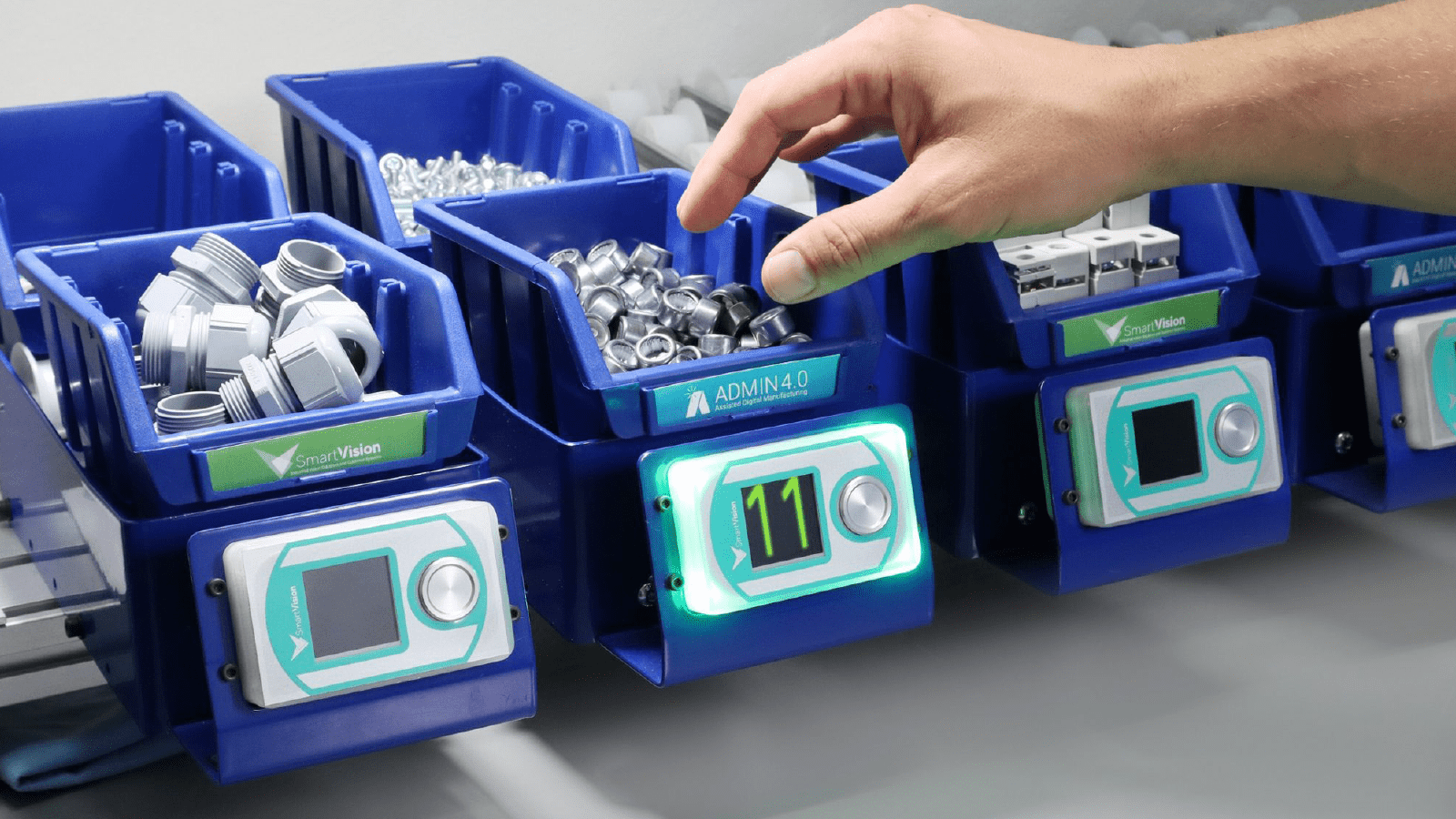

Pick to light

So how to ensure that the operator always reaches for the right component so that the interplay between the hands and the machine is perfect? This is exactly what the material guidance “pick to light” brings. The name itself suggests the way in which it works with the operator. He does not need to remember all the positions and order of the individual components but only needs to see the light signal and the number of pieces to be picked on the display, by which the system selects the material for the operator so that it is used correctly throughout the production process. The pick to light material control has positional weighing of the material. The system knows exactly how much material the operator has picked from the position.

Artificial intelligence and quality control

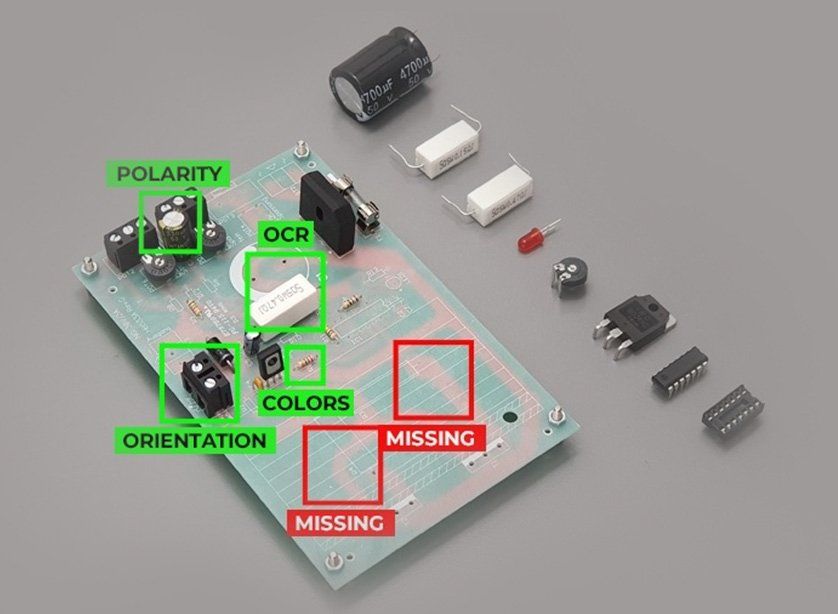

Today, there is perhaps no industrial sector where CCTV is not used to improve output quality. However, if we want to replace the operator’s eyes, it is not only important to see like a human being but also to think and learn like one. Artificial Intelligence combined with quality control allows adaptation to different lighting conditions or changes in the design of products and individual components, thus providing continuous adaptation to the operator’s environment.

The system is not set up but learns, so no expert is required. Learning is continuous just as it is for humans – the more they see, the more robust their behavior. It can recognize the correctness of components, orientation, position, or surface design defects.

Quality control

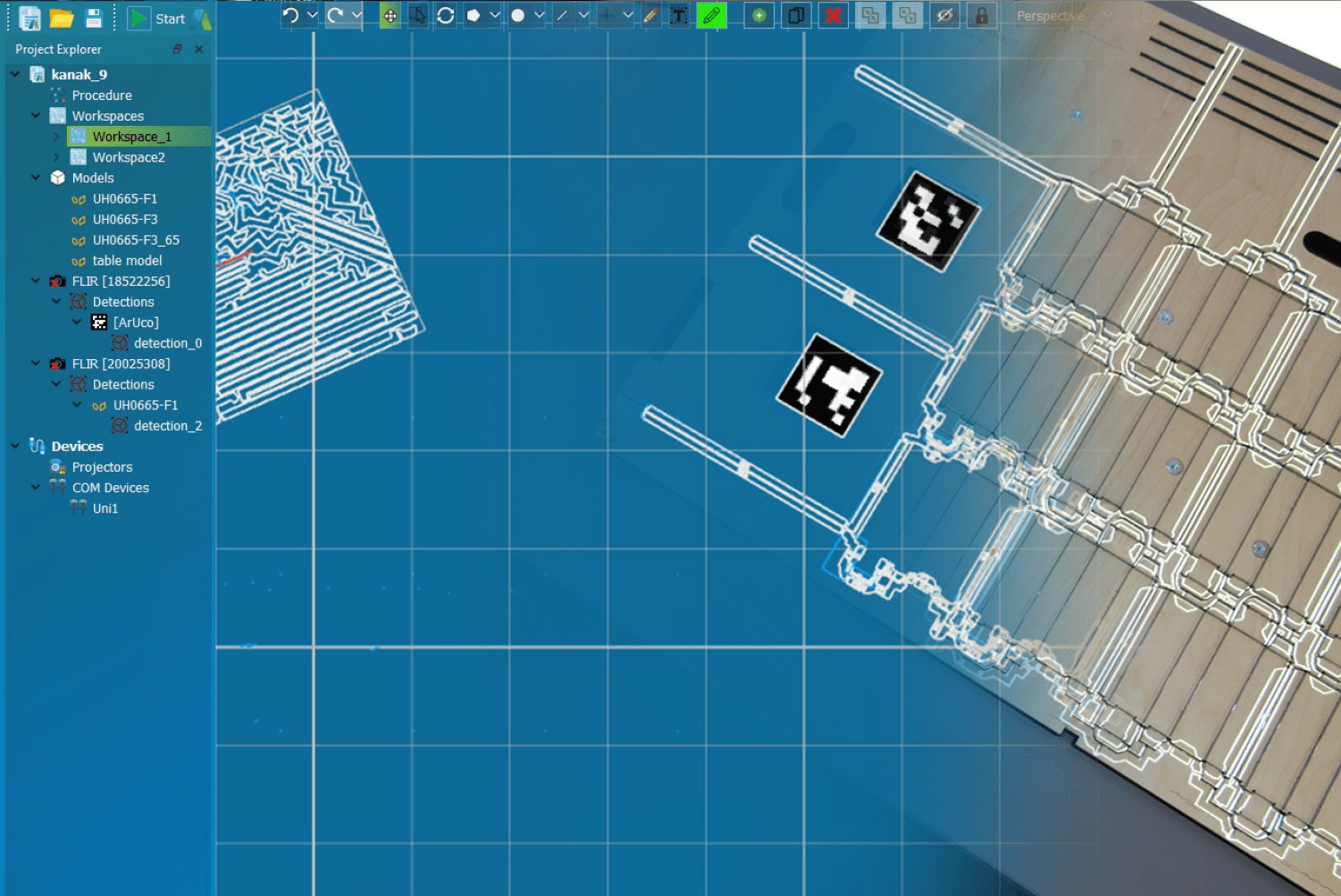

CAD, linking technical documentation and data processing

Linking with CAD is a necessity for digitizing technical documents and transforming them into production processes. It only takes a few seconds to automatically create a control program for operator visual guidance and quality control, representing true digitization in the manufactory and using it to your advantage.

Linking with CAD