Bridge To Vision

Module designed for camera quality control in connection with the operator and built-in to the manufacturing station.

Module designed for camera quality control in connection with the operator and built-in to the manufacturing station.

Module designed for collaboration with the operator using camera control and interactive visual guidance.

Module designed for complete process digitization using camera control, visual guidance and material management.

Module designed for camera quality control in connection with the operator and built-in to the manufacturing station.

Module designed for collaboration with the operator using camera control and interactive visual guidance.

Module designed for complete process digitization using camera control, visual guidance and material management.

Bridge serves as an all-in-one visual guidance and control module enabling easy and quick deployment of the ADMIN4.0 assisted digital production system, facilitating an interactive work environment in an intelligent factory.

Bridge serves as an all-in-one visual guidance and control module enabling easy and quick deployment of the ADMIN4.0 assisted digital production system, facilitating an interactive work environment in an intelligent factory.

Bridge serves as an all-in-one visual guidance and control module enabling easy and quick deployment of the ADMIN4.0 assisted digital production system, facilitating an interactive work environment in an intelligent factory.

The compact module of the ADMIN4.0 visual guidance and control system allows for easy installation in any space and workplace, without the need for structural preparation. It provides an all-in-one solution for deployment variability.

The Pick to Light system is a crucial feature in the workplace that connects material positions required for product assembly and individual steps of product completion using lights and addressed LED tubes.

The simple installation and adjustment of positions are a unique solution in line with the Bridge system.

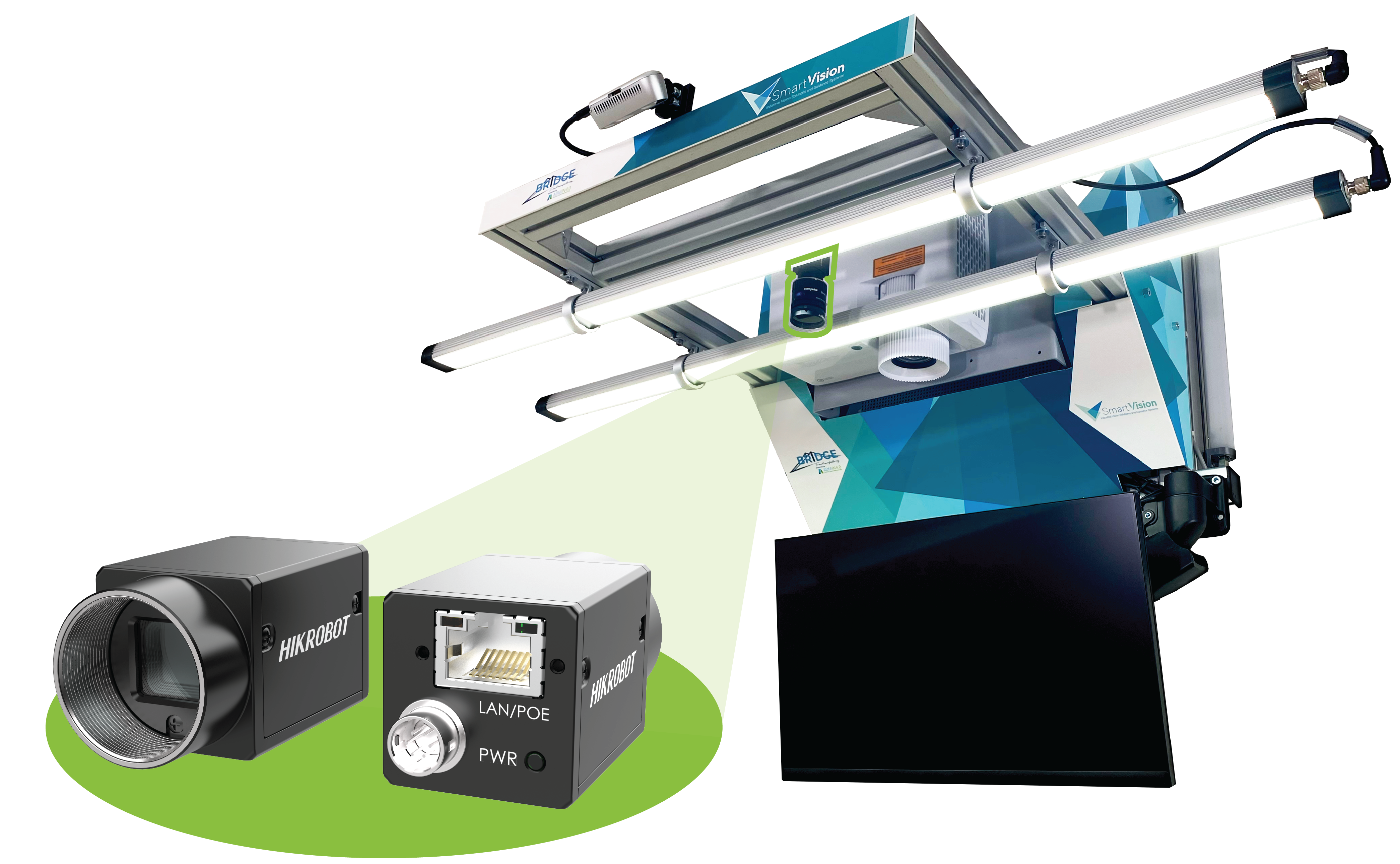

Fast and collaborative quality control is achieved using artificial intelligence and machine learning, along with a precise and rapid 2D camera.

The camera produces high-detail images and, through polarization, eliminates surrounding environmental noise. This makes it suitable for use in a factory environment and enables high-precision measurements down to tenths of a millimeter.

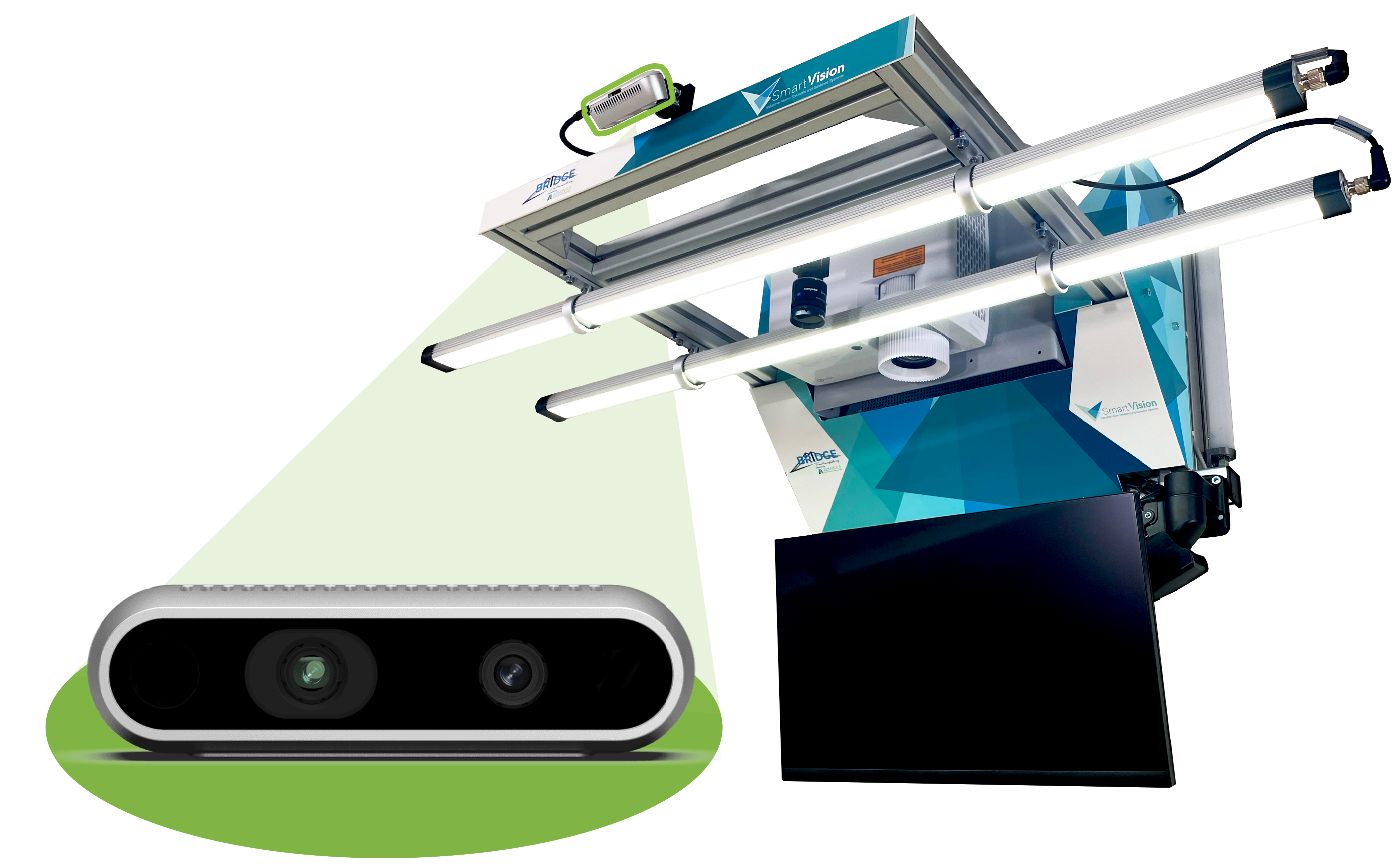

Monitoring the operator’s hands involves capturing spatial information about the workspace using a 3D camera.

This system enables the recognition of material manipulation and evaluation of the correctness of the removed material.

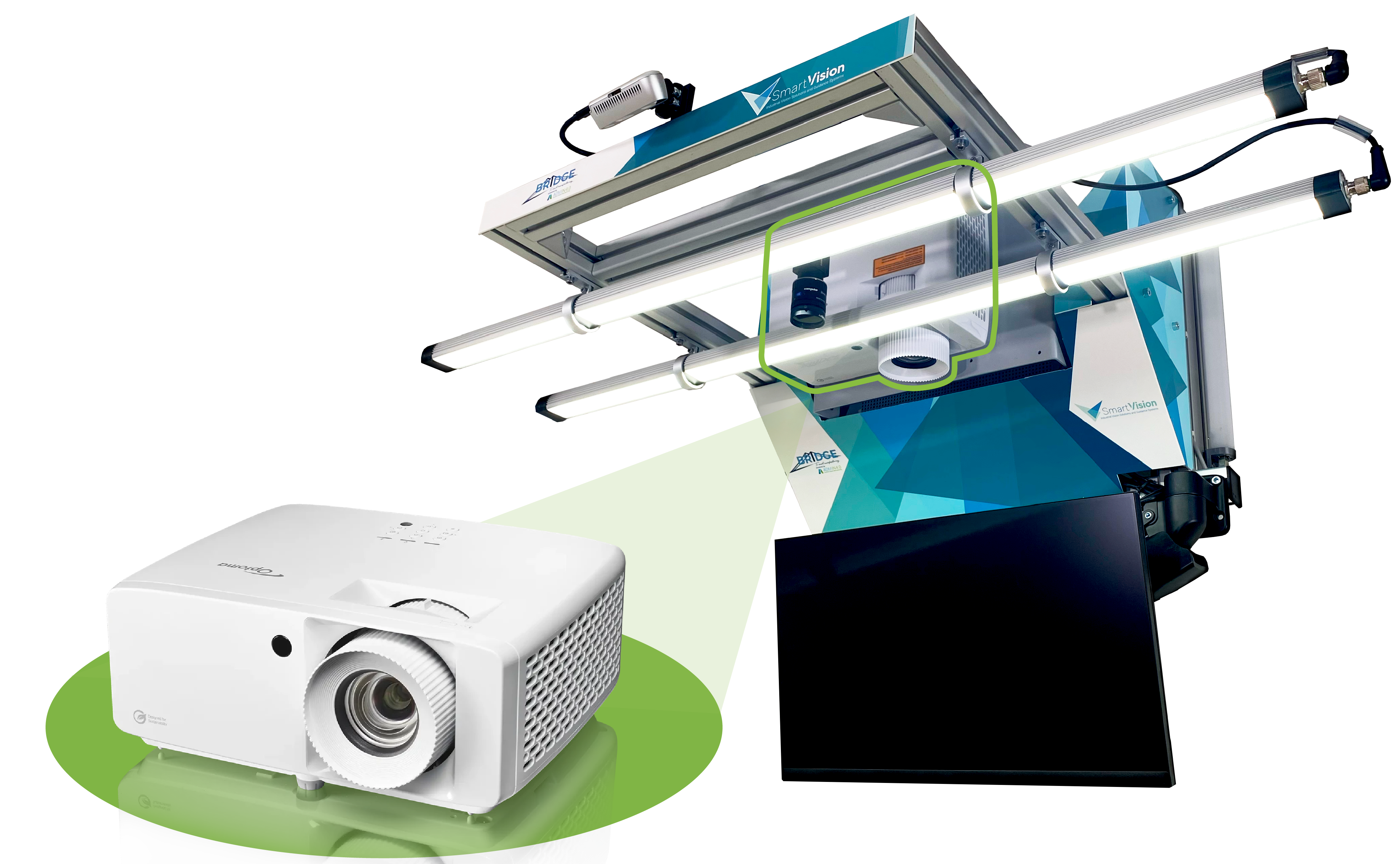

Visual guidance involves the use of augmented reality, employing a video projector to interactively navigate the operator in the space using video, images, animations, and CAD shapes.

The projector has a variable range of up to 2 meters, which can be further extended by connecting multiple projection units.

The control system is designed to provide high performance without interfering with the working environment. It is integrated into the Bridge module and the associated monitor.

Unlimited CPU i7 performance and NVIDIA GPU power ensure fast machine learning training and program execution.

The status bar is an LED addressable light tube that indicates when production goals have been met and the production pace that has been achieved.

This allows for quick recognition of any deviations from the production plan from a distance.

The range of camera and projection equipment varies. For projectors, the projection width starts at half a meter with an installation height of one meter and can extend up to two meters at the same installation height or higher.

The 2D camera has variable installation heights, ranging from half a meter with a range of a few centimeters to several meters. If the coverage of a single device is insufficient, multiple devices can be combined to cover an unlimited area.

The M5 control module provides access to the essential and most frequently used functions of the station, including procedure, lighting and station control. It also displays necessary information for the operator, such as the amount of material to be removed or the system’s current operation status.

The M5 control module provides access to the essential and most frequently used functions of the station, including procedure, lighting and station control. It also displays necessary information for the operator, such as the amount of material to be removed or the system’s current operation status.

Deployment flexibility lends a helping hand to operators in a wide range of applications:

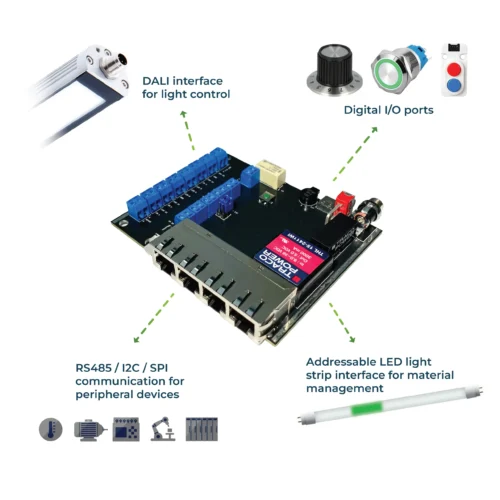

UniBox is a multifunctional I/O module that mediates control inputs and outputs from 5 to 24V. It supports I2C, SPI, RS485 communication, DALI lighting regulation, and connection of Pick to Light material LED tubes.

The setup includes two LED tubes that emit polarized light, which helps to eliminate unwanted environmental lighting effects. Each tube has a power of 96W.

The precise lighting creates an ideal environment for quality inspection and ensures the comfort of the operator during work.

Using the control wheel, the operator can adjust the lighting level to ensure comfort when working with the ADMIN4.0 system.

Using the control wheel, the operator can adjust the lighting level to ensure comfort when working with the ADMIN4.0 system.

The system is plug-and-play and is ready for immediate use after unpacking and attaching it to the workplace using a few mounting elements.

If you use the product preset option, the time until the system is put into production is reduced to hours, speeding up the entire commissioning process.